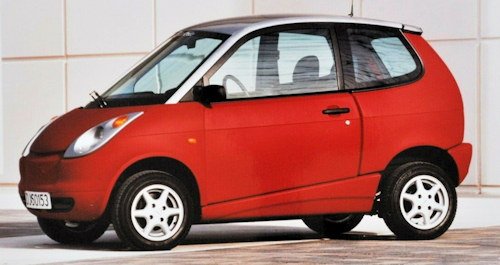

Ford Think City

|

|

|

Production period: |

1999-2011 |

|

Class : |

motor car |

|

Body versions : |

hatchback microcar |

|

Engines: |

Electric motor : 30 kW |

|

Length: |

3120 mm |

|

Width: |

1604 mm |

|

Height: |

1548 mm |

|

Wheelbase : |

1970 mm |

|

Curb weight : |

1113 kg |

The Think City is an electric car manufactured as the A266 Ford Think from November 11, 1999 to March 22, 2002 and by the Norwegian company Think Global from 2007 to 2011

History

The two-seater is powered by 19 water-cooled nickel-cadmium batteries and reaches a maximum speed of 100 km / h over a range of approximately 85 kilometers. The Ford Think weighs about 940 kg. The base is made of steel, while the body is made of a thermoplastic material .

After about 5 hours on a 230 volt outlet, the batteries are 80% charged, they are fully charged after about 8 hours.Ford has discontinued production of this vehicle model.

Currently the only model is the Think City. The microcar is designed as a city vehicle. It is usually a two-seater, but in the trunk can be installed an additional bench for children. The model is equipped with ABS , electric windows , electric mirrors, central locking , from model year 2011 also with air conditioning and ESP .

To realize the drive , a 30 kW electric motor with 90 Nm (operating power: 17 kW, input voltage: 188-407 V, output voltage: 14.5 V, current: 0-100 A) was used until August 2010 (1st generation of the electric drive, Power Conversion Unit (PCU)).

With a maximum range of 160 km (about 125 km at 100 km / h, the maximum speed), it surpasses twice that of electric vehicles of earlier construction. This is a sodium-nickel chloride battery used, also called zebra battery . This has a working temperature of 270 ° Celsius and has an energy density of about 94 Wh / kg-120 Wh / kg in practice. (Theoretically, up to 150 Wh / kg would be possible.)

Critics doubted the durability of the Zebra battery , although this type of battery has been developed for years and u. a. also in military applications (torpedoes, submarines) is used. The Think City pricing model was initially based on selling the vehicle but letting the battery be rented out. So the risk would have remained with the manufacturer. The manufacturer, however, seems confident in its cause, as its operational capability has already been demonstrated to a high degree. Dr. Cord-Henrich Dustmann, former head of zebra activities at MES-DEA, reported in a lecture in June 2004 regarding the lifetime of a test battery that a battery has been in operation for eleven years and has undergone over 3000 charging cycles. MES-DEA gives a 5-year warranty on Zebra traction battery in Think City, as of 2010. In these vehicles, the removable capacity was reduced by software, so that the range was reduced from 180 to 160 km. However, a larger scale has not yet succeeded because the battery type is almost unknown, although it was originally intended to be used in the Mercedes A-Class. The Zebra traction battery had been developed by AEG, a former Daimler subsidiary. In August 2010, five Think City with ZEBRA batteries took part in the e-Miglia 2010, the first international electric car rally across the Alps, which convinced many doubters.

In the meantime, the company Think Global AS also offers a lithium-ion traction battery with the same range but smaller dimensions as an alternative to the Zebra traction battery , since this type of traction battery has a slightly higher energy density and does not have to be constantly heated. However, lithium-ion batteries are temperature-dependent in their performance, which can lead to loss of range in cold ambient temperatures (compared to normal or warm temperatures).

The Think City control units have been incorporated into the electronic diagnostic systems for garages, so that now a nationwide workshop network for the electric car is available. This cooperation between Move About and Bosch originated in the German electromobility projects of the economic stimulus package II, since the Think Citiy is used in several model regions (BMVBS) and model projects (BMWi).

In 1999, Ford acquired a majority stake in the small Norwegian car manufacturer Pivco Industries and renamed the company Think Nordic AS to include its electric car development under the new name Think City (A266) in the current PIV 4 model to be able to record. The background to this was a law by the California Air Resources Board , an environmental agency in California ( USA ), which imposed on the automotive industry to produce at least 10% of its vehicles without emissions in a phased approach by 2005 A legal action was brought against this regulation in 2001.

Following the banning of the implementation of this regulation by a decision of the California State Court in June 2002, he resulting subsidiary, Think Nordic AS, which was additionally flanked by Ford's Think Technology and Think Mobility businesses, took shape The Think Group sold again in February 2003, although shortly before the entire production site had been converted to the successor model (A306). As justification for the sale, Ford said the sale of Think City electric cars would not have been as successful as those in charge would have hoped, and eco-friendly alternatives such as the hybrid carhave been developed to market maturity. In addition, one would have hoped for more political initiative, which supports the market for electric cars. In the two and a half years (from November 1999 to March 2002) Ford has produced 1005 A266 vehicles, which have been sold in 14 countries. The sales figures were, from the point of view of a large automobile company - such as Ford - viewed, not so satisfactory that after changing the legal reality in California one would have been so readily ready to get involved in the market segment of electric cars.

With the completion of Ford's production of Think City in August 2002, the future of Think Nordic was uncertain for a long time, and further or even mass production was unlikely.Only after KamKorp Microelectronics Inc (Switzerland) bought the company in February 2003 did it move forward again. Just one year later in March 2004, the jointly developed prototype of the Think Public was presented to the public.

The business concept for the Thinkbus microbus provided that it should be rented by customers for urban transport purposes. But it lacked in the implementation. As a result, the company was in financial distress at the end of 2005 / beginning of 2006 ( bankruptcy around February 2006). As a result, at the end of March 2006, Think Nordic was sold to the Norwegian investor group InSpire , which renamed the company Think Global and, apart from the restructuring , changed its direction and product policyTheir declared goal was to turn Think Global into an all-electric vehicle manufacturer with a number of models in the form of a range of products on the market to meet different user needs.

As of November 2007, Think Global AS produced an improved model Think City, which was also equipped with ABS , air conditioning , power windows , airbags , power steering and a sunroof . Groundbreaking, however, was the equipment with an optional telematics unit (RAC - Remote Access Control), whereby the car could be used ex works as a car sharing vehicle. Cars with this option have a button labeled "Assist" in the center console. If you pressed this button longer, you were connected to a call center, similar to what GM Onstar or other providers offer.

In March 2008, Think Global reached an agreement to cooperate with the lithium-ion battery manufacturer and General Electric subsidiary A123 Systems . In addition, General Electric invested $ 4 million in Think Global and $ 20 million in A123 Systems to increase production capacity at the subsidiary, enabling it to deliver the required lithium-ion batteries to Think can.

Contrary to the spirit of the March agreement, however, Think Global successfully tested three lithium-ion battery packs from EnerDel in June of the same year - a competitor of A123 Systems - on test vehicles near Indianapolis, at a pre-planned Think production facility.

In spite of the visible progress made by the company, with the aim of increasing the number well over 2,500 per year, Think Global was in financial turmoil in mid-December 2008, with Think CEO Richard Canny saying the company needed it for its short-term Financial operations urgently required between $ 14.5 and $ 29 million in loan guarantees from the Norwegian government, otherwise production would have to be halted and continued until the following year and up to 70 percent of the workforce would be laid off. It was necessary to secure credit lines, which had to be approved by the banks.An intervention by Charles Gassenheimer, head of battery supplier EnerDel, provided a loan guarantee of NOK 40 million ($ 5.69 million) in January 2009, ensuring short-term liquidity.

Finally, at the end of August 2009, a recapitalization of the company was announced by existing and new investors: after that, US battery manufacturer Ener1 (Fort Lauderdale, Florida), a parent company of EnerDel , acquired a 31 percent stake in Think Global; also occurred Rockport Capital Partners (Boston, Massachusetts), Element Partners (Philadelphia) and Kleiner Perkins (Palo Alto, California) added, further Valmet Automotive , headquartered in Finland and Investinor, an investment fund supported by the Norwegian government. For Valmet Automotive's minority stake in Think Global and the agreed technical cooperation of both companies, Valmet was granted permission to build the Think City in Finland. But not only that: this step was accompanied by the outsourcing of the Norwegian-based vehicle assembly to Finland. In fact, the production of Think City vehicles started in December 2009 at Valmet in Uusikaupunki, Finland.

In return, EnerDel's acquisition of Ener1 at Think Global resulted in longer-term exclusive rights to supply Think with batteries to populate its early and upcoming models. These exclusive rights probably related only to the vehicles that Think Global intended to produce in the US, as Think later announced on January 25, 2010, that EnerDel would be responsible for supplying all of them in the US and 60 percent of vehicles produced in Europe would be charged with batteries. This means that A123 Systems Think Global has supplied some of the remaining 40 percent of Europe's battery power to Europe, and the relationship between Think Global and A123 Systems has not simply been resolved, but has continued as agreed, as A123 Systems and EnerDel have previously supplied Think Global with batteries and accordingly, there has been some continuity in the business relationships between the three companies.

In 2010, Think Global opened a new vehicle plant in Elkhart, Indiana. The first vehicles from the local production were delivered in mid-December of 2010.In March 2011, Valmet Automotive suspended its production of Think City EV in Finland until further notice. Think in Norway also suggested that demand for the City model was extremely modest at the beginning of the year. This has once again put Think Global in financial straits, as such a decision effectively put an end to Think Global's entire European production. In May 2011, Ener1 wrote off its millionaire investment in the troubled Norwegian electric car manufacturer Think Global and returned all shares in Think Holding.

Manuals

-

Ford (europe) Previous 107 / 128 Next