Britain

- Details

- Parent Category: Motor car History

- Category: Britain

John Cooper Works History

Farnborough U.K.

John Cooper Works (JCW) The company was founded in 2000 by Michael Cooper, the son of John Cooper, a sports car designer and tuner of the original Mini Cooper. It is a British manufacturer of tuning parts and accessories and has been a BMW Group brand since 2007 for mini models and accessories of the same name.

History

In January 2007, BMW acquired the trademark rights of John Cooper Garages, making the John Cooper Works brand officially part of the MINI brand since 2008. In the early years John Cooper Works appeared as an independent tuner. The product range included tuning kits for the models Mini Cooper and Mini Cooper S.

Cooper

The first tuning kit from JCW was a 94 kW (126 hp) conversion for the Mini Cooper. This conversion kit contained the following components:

- Machined cylinder head

- air filter

- Exhaust system from catalyst

- Software adaptation of the engine control

- emblems

Despite the price of over 2000 €, this kit only achieved a power increase of 8.2 kW (11 hp), a sportier sound and a better response. The main advantage was that the conversion could be carried out without loss of the factory warranty. In 2004, JCW quit this sentence and presented at the same time a sound kit for the Cooper. The sound kit consisted of a new intake system, an exhaust system and adjustment of the control units.

Cooper S R52 and R53

The first tuning kit for the Cooper S was a conversion kit to a total of 147 kW (200 hp). This kit was introduced in 2002 and consisted of the following components:

- Machined cylinder head

- Bigger, faster rotating compressor

- Improved spark plugs

- Improved exhaust system

- Software adaptation of the engine control

- Emblems, as well as individually numbered engine signs and a certificate with the signature of Mike Cooper

First, this kit had to be retrofitted by the mini-dealer. Only at the end of 2005, the Cooper S could be ordered directly from the factory in this configuration.

In 2005, an additional upgrade was also presented, which brought a greater performance increase to 155 kW (210 hp, specified in relevant vehicle purchase portals with 211 hp) and additionally contained the following components:

- Improved injectors

- Adaptation of the software

- Improved intake system and air filter

This service package can / could be retrofitted into older models of the series. At the same time appeared a "JCW Sound Kit", consisting of an exhaust system and air filter, which promised for about 1100 a sportier sound and a power increase of 2.2 kW (3 hp).

Cooper S R55, R56 and R57

In 2007, Mini introduced the JCW Tuning Kit for the new R56 version of the Cooper S. The new model was charged by a turbocharger instead of the compressor. The kit was different from the previous version and consisted of an improved intake system, exhaust system and software adaptation. It brought a performance increase of 13 kW (17 hp) to a total of 143 kW (192 hp), a torque increase of 10 Nm to 250 Nm (270 Nm with over boost), acceleration of 0-100 km / h in 6.8 seconds, as well a top speed of 232 km / h. It became known as the "Stage 1 Kit", although this designation was never officially used by JCW or BMW.

According to Mike Cooper, this kit made it possible to produce the "fastest mini ever produced”, notably by adding torque and acceleration, making the car faster in some situations than the 163 kW (218 hp) Mini JCW GP,

In 2011, the JCW tuning kit for the Cooper S LCI (135 kW) was adapted. It consists of an improved exhaust system, intake system, exhaust manifold and software adaptation. The kit also includes a sticker on the engine with a unique serial number, as well as JCW emblems on the front and rear. With a power increase of 12 kW, a total output of 147 kW is achieved.

Integration into the MINI brand (since 2007)

In 2007/08 the acquisition and integration into the BMW Group took place. Since then, revised MINI models can be ordered directly from the factory under the JCW brand.

John Cooper Works R56

This is not another conversion kit, but a completely reworked version of the R56 Mini with model name MF91 (Clubman version MM91). This vehicle has been sold by the dealer network and includes some changes from the 143kW (192hp) Power Kit:

- Peak power of 155 kW (211 hp) at 6000 rpm and a torque of 260 Nm (280 with over boost). This is due to an improved turbocharger, larger exhaust system and sportier software customization. Acceleration from 0 to 100 km / h in 6.5 s (6.8 at the Clubman). Fuel consumption and emissions are also on the rise, although the 143 kW (192 hp) kit brings no change to the 130 kW (175 hp) standard version of the Cooper S.

- Electronic Differential Lock Control (EDLC). This is infinitely adjustable between 0 and 50%, in contrast to the permanent 30% of the optional LSD in the R56 Mini Cooper S.

- DTC (Dynamic Traction Control) as found in all current BMW models. The John Cooper Works is the first Mini to be delivered with DTC. The main difference between DTC and DSC is the ability to adjust the parameters for the traction and stability control system to allow a sportier ride without having to completely shut down the stability control.

- Brembo pot brakes, consisting of red aluminium brake callipers with John Cooper Works logo on the front, red one-piston callipers on the rear, perforated and ventilated brake discs 316 × 22 mm at the front and 280 × 10 mm at the rear.

John Cooper Works GP (2013)

The Mini John Cooper Works GP was only built in an edition of 2000 pieces. This model is powered by a 160 kW (218 hp) turbocharged 1.6-liter 4-cylinder engine and accelerates from 0-100 km / h in 6.3 seconds, reaching a top speed of 242 km / h. The GP features exclusive 17-inch mini-challenge wheels, high-performance tires designed in cooperation with Kumho, adjustable suspension, 6-piston Brembo front brakes, red mirror brake callipers, RECARO sports seats (with side airbags) and a rear strut bar.

Mini confirmed a lap time of 8:23 minutes on the Nürburgring an improvement of more than 19 seconds over the previous model.

John Cooper Works F56 (2015)

At the end of 2015, a new JCW model was launched. It was a derivative of the F56 series, which was built since 2014 as the third edition of the "New MINI" under BMW direction.

This new John Cooper Works brings next to changed exterior dimensions, which make him bigger and beefier, a 2.0-liter twin-turbo engine, the standard 231 hp catapult him in the switching version in 6.3 seconds from 0 to 100 km / h.

Since March 2009, the Mini Convertible is available as JCW.

Coupe

The Mini Coupe was available between October 2011 and May 2015 as JCW. The vehicle was powered by the 1.6-liter gasoline engine with 211 hp. At 100 km / h, the Coupé accelerates in 6.4 seconds, the top speed is 240 km / h.

Of this vehicle there is only one for the long-haul homologated racing variant, this was used in 2018 by the racing team Racing4Emotion in the VLN at the Nürburgring.

Roadster

The coupe-based Mini Roadster was available between March 2012 and May 2015 as JCW. The vehicle was powered by the 1.6-liter gasoline engine with 211 hp. At 100 km / h the roadster accelerates in 6.5 seconds, the top speed is 237 km / h.

Countryman

The John Cooper Works Countryman is Mini's first 5-door JCW. This was presented in 2012 at the Geneva Motor Show. The SUV is powered by a 218 hp 1.6-liter gasoline engine, which accelerates the SUV in 6.9 seconds to 100 km / h. The top speed is the manufacturer with 228 km / h.

Based on the second generation of Countryman the JCW makes 231 hp from a two-Liter gasoline engine. 100 km / h are reached after 6.5 seconds, the top speed is 234 km / h.

Paceman

The SUV Coupé Mini Paceman was also available between March 2013 and November 2016 as JCW. As well as the first generation of the Countryman, the vehicle was powered by a 218 hp 1.6-liter gasoline engine. This accelerates the SUV in 6.8 seconds to 100 km / h. The maximum speed is the manufacturer with 229 km / h.

John Cooper Works GP Concept

At the International Motor Show in Frankfurt am Main in September 2017, the concept car Mini John Cooper Works GP Concept based on the Mini F56 was presented. The production car will succeed the John Cooper Works GP. The concept vehicle has the number 0059 on the flanks. This is a reminiscence of the first year of production of the Ur-Mini. The taillights are reminiscent of the Union Jack.

- Details

- Parent Category: Motor car History

- Category: Britain

Caledon Motors Ltd

Commercial vehicle manufacturer Scotland 1914-1926

Caledon was a former early Commercial vehicle manufacturer at the firm's Duke Street works in Glasgow Scotland.

History

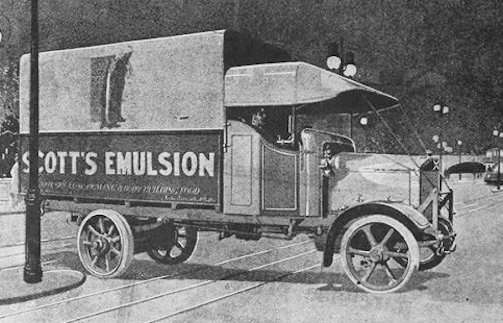

When the first World War I broke out Scottish Commercial Cars Glasgow, the Scottish agent for Commer Cars at the time. found itself without any vehicles as these were then diverted for the war effort. To fill the gap, a new 4-tonner was structed using a 40hp 4-cyl Dorman type petrol engine, along with a Dux 4-speed constant-mesh gear-box with chain drive.

This became Called the Caledon it was capable of speeds up to only 19 kmh but from the start was hit with mechanical problems, which included severe vibration.

In 1919 the company re-named Caledon Motors Ltd the range now expanded to include also vehicles from 1 1/2 to larger 7-ton capacities with a shaft-drive passenger chassis. A new engine production area was organized to combat the lack of engines, but the development of a sleeve-valve engine cost was expensive much and took so much time to complete

so the company was forced into liquidation in 1922. The company’s Assets along with the premises and rights to the name were re-acquired by Scottish Commercial Cars Ltd

which then proceeded with the new range but again with the Dorman-powered and Hercules-engine forward-control passenger model.

By 1924 a larger 10-ton rigid 6-wheeler was announced, its Dorman engine being replaced later by a Buda unit. This is believed to have been Britain's first rigid-6 lorry.

By the end of 1926 the business had been sold to Richard Garrett & Sons Ltd, who subsequently built three Garrett-Cale-don trucks.

- Details

- Parent Category: Motor car History

- Category: Britain

Baron Motors Ltd

Commercial vehicle manufacturer Borehamwood, Herts England 1957 to 1969

Baron Motors Ltd was a Commercial vehicle manufacture founded at Borehamwood, Herts, England UK.

History

Baron Motors developed a series of economical commercial chassis aimed at under-developed countries. Despite lack of co-operation from certain component suppliers, a 7-ton bonneted prototype was ready by 1959, followed by second and third prototypes incorporating numerous improvements. By 1964 the first production models had been constructed,

comprising the bonneted 6-ton'Master' BN6, bonneted 7-ton'Senior' BN7 and a forward-control passenger chassis intended for 38/44-seat bodywork.

The BN6 and BN7 goods models were similar to the normal-control Commer 'Superpoise' of the day, having the same Airflow Streamline cab or front-end structure. However, it was an assembled vehicle with specially designed uprated chassis frame supplied by Rubery, Owen & Co Ltd, having an Eaton 2-speed axle, a 120bhp Perkins 6.354 diesel engine, and a 32-cm single dry-plate clutch with hydraulic withdrawal mechanism and 4-point mounting in unit with the gearbox. The 6-tonner had a 4-speed synchromesh box and, with twin rear tyres as standard, produced a maximum speed of 55 mph with a bottom gear gradient capable of 1 in 2.3 in low axle ratio or 1 in 3.2 in high ratio, enabling the vehicle to cope with most gradients. Whilst the chassis frame was of riveted pressed-steel construction, items that might be replaced in service, such as spring hanger brackets, were bolted in place. Semi-elliptic leaf springs were fitted throughout, with helper springs at the rear and shock absorbers standard at the front but optional at the rear. Also optional were single rear tyres, with a front axle rating of 3 tons.

The BN6 had a gross weight of 9525kg and was available only with a wheelbase of 420cm. The 7-tonner had a wheelbase of 490cm and a much heavier chassis frame, although suspension, brakes and rear axle were the same as for the 6-tonner. This model had a 5-speed constant-mesh box and optional single tyre equipment. Front axle rating was 4 tons and gross vehicle weight 10,432kg. The passenger model was a foreward-control version of the 6-tonner, but it is doubtful if many were sold. Complete vehicle kits were assembled and packed in a factory at Northampton. Although listed for export until 1969, few were actually supplied.

- Details

- Parent Category: Motor car History

- Category: Britain

Armstrong-Saurer Commercial Vehicles Ltd

Commercial vehicle manufacturer Newcastle-upon-Tyne England 1931 to 1937

Armstrong-Saurer was a Commercial vehicle manufacturer during the pre-war years of the 1930s.

History

In 1931, Sir W G Armstrong- Whitworth & Co Ltd took over manufacture under licence of the Swiss Saurer truck range, establishing Armstrong-Saurer Commercial Vehicles Ltd, Newcastle-upon-Tyne, to assemble these and develop new models for the UK market.

The first were displayed at the 1931 Commercial Motor Show, comprising 4- and 6- wheeled rigid chassis with petrol or diesel engines. By 1933 only 6- cyl diesel vehicles were listed,

ranging from the 4x 2 'Defiant' to the 12-ton 6-wheeled 'Dominant’, which had a pressed-steel rear bogie conforming to UK weight replaced by the lightweight, 8-ton payload 'Dynamic' 4-wheeler in' Active' 4-wheeler for 7/8-ton pay- loads and the 'Effective' 4-wheeler for drawbar work.

Passenger models were not listed, so the company gave Dennis Bros sole rights to fit Armstrong-Saurer diesels in theirs. Most famous of all Armstrong-Saurers, however, was the 22-ton GVW 'Samson' rigid 8-wheeler, announced in 1934. This was very advanced, having a full air braking system acting on all wheels, and a fully- floating double-reduction spiral-bevel third axle with trailing fourth, drive being via a 4-speed crash box with optional 2-speed auxiliary.

In 1935 the company began experimenting with an unusual dual-turbulence 3.62-litre diesel engine that develops 120 h.p. at 1.800 r.p.m. with the intention of fitting this in a medium weight truck. Additional finance was needed if this was to be successful, but none was forthcoming and the company went out of business.

- Details

- Parent Category: Motor car History

- Category: Britain

Argyle Motor Mfg Co Ltd

Commercial vehicle manufacturer Scotland 1970-1973

The Argyle Motor Mfg Co Ltd was registered in 1968 by Argyle Diesel Electronics Ltd, East Kilbride, Lanarks, to manufacture a 16-ton GVW rigid goods model called the 'Christina', aimed exclusively at Scottish operators, using the company's own chassis frame, a Perkins 6.354 diesel engine and a Motor Panels cab.

The 'Christina' also had a single-dry plate Borg & Beck clutch, 5-speed Eaton gearbox, 2-speed Eaton bevel-and-pinion rear axle, and a Kirkstall front axle. Later, this 5.28-m wheelbase load-carrier was joined by a 3.8-m wheelbase tipper version, while plans were drawn up for an articulated model to be known as the 'Linsay' and a 'Karen', but neither saw the light of day. In 1973 a giant solid-tyred molten steel hauler called the 'Trilby' was delivered to the British Steel Corp for use in South Wales, making this the only non- Scottish customer for the Argyle. Capable of hauling 120 tons, this had a Cummins diesel engine.