Technical Guides

Automotive Paint Blistering

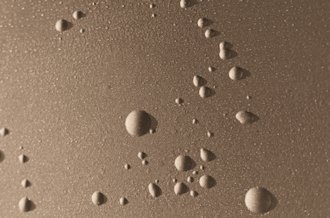

This section includes Automotive paint Blistering bubbling, pimpling, pin holing, pitting and pock marks. How to repair and avoid this.

Generally, to repair if damage is extensive and severe, paint must be removed back down to the undercoat or even metal surface, depending on depth of blisters. But a repaint. In less severe cases, blisters may be flatted out again, and repainted following the guides below.

Paint Blistering Cause

- Usually caused by moisture becoming trapped between metal and undercoat, or between undercoat and colour coat, expanding, and forming small to large rounded blisters. Other causes or contributing factors are oil, dirt, rapid changes in temperature, large temperature differential between surface and paint being applied, cheap thinner, salts

from water used for flatting. The water causing the blistering may come from the flatting operation or condensation caused by the cooling effect of spraying.

Water or oil may come through the compressed air line.Since no paint film is completely impervious to water or water vapour, some moisture often gets under the film. When this occurs, heat (from sunshine, etc.) will vaporize the moisture, and, if the pressure developed is great enough, blisters will form. This type of blistering is more prevalent in rainy or humid conditions. - Cheap, fast thinner; insufficient thinner; too high air pressure; and dry spraying of undercoats (causing porosity and air pockets in the undercoat film) can cause blistering. Degreasing with petrol often results in blisters forming in the finish. Application of heat to a film containing volatile solvents.

- Insufficient drying time and too heavy application of the undercoats may trap solvent, which later escapes to cause blistering of the colour coat.

Paint Blistering Prevention

- Do not allow water droplets to dry by themselves. Always wipe off visible water to avoid chemical deposits. Check compressed air regularly for oil and water. One method of checking is to blow the air against clean glass or white paper. Inspect for oil or water droplets.

- Allow sufficient time after wet flatting and blowing off for undercoat to dry out. On particularly humid days, several hours may be required. After wet flatting, blow out all cracks and crevices thoroughly with clean dry compressed air.

- Apply undercoats in thin, wet films, allowing sufficient flash-off time between coats to avoid trapping solvents Do not apply heat to heavy films which contain volatile solvents. Use a good thinner to avoid condensation of atmospheric moisture on surface.Allow metal and paint to come to equal temperatures, 16-24 °c, before painting.

- Keep air pressure consistent and as low as possible with good atomization.Check in your tools information manuals on how to do this for your equipment.

- Replace worn parts and clean regular, maintenance on paint equipment is essential for a good finish store in dry dust free containers if damp dirty location.