Ford Continental Division History

The Continental Division was a division of the Ford Motor Company for the construction of a luxury car in the top market segment. It was introduced in 1952 and merged with the Lincoln Division in 1959 before being wholly abandoned after 1960.

History

Their Continental automobiles were built from 1956 to 1960. There is no relationship with the Continental Automobile Company from 1933-1934 and its parent company, Continental Motors Corporation.

The American luxury car manufacturer Lincoln first used the term "Continental" in 1939 for a derived from Lincoln Zephyr convertible for Edsel Ford. The resulting demand led to a series production. In 1941, with a coupe as a supplement to an independent series above the Zephyr, which could be at least partially compensated for the loss of the large K models. The Eugene T. Gregorie extraordinary designed model was quickly recognized as a design icon and is one of the classics of pre-war design. Until the cessation of production, two rather less successful facelifts took place (1942 and 1946) and improvements to the engine.

A Until the early post-war period, there was a huge innovation backlog. Ford used throughout the group until 1948 rear transverse leaf springs, mechanical brakes and no shift aids or even an automatic transmission. The Continental offered until 1948 had been slightly revised stylistically; technically, however, they were at pre-war levels. The side-controlled V12 Engine had been slightly modified; but still goes back to the zephyr of 1935.When new models were introduced across the Group in 1949, the focus was naturally not on the Continental.

The decision for the new Continental was made in 1951. The project was placed under William Clay Ford Senior's position as Head of the Special Products Division. William Ford is a son of Edsel Ford, the younger brother of Henry Ford II and grandson of Henry Ford, and already had some management experience at the time. Officially, the Continental Division was used on 1 July 1952. She came out of the Special Products Division; William Ford became their general manager. She moved into premises on Oakwood Boulevard in Dearborn (Michigan) southwest of Detroit. Out of 1,300 Lincoln dealerships, 650 accepted the offer to sell the Continental.

Chief designer for Continental was John Reinhart, who had only since 1952 from his position as chief designer of Packard to Ford. He was supported by the legendary designer Gordon Buehrig, who had designed in the 1930s, some eye-catching bodies for Duesenberg and written with the Cord 810 design history. Because the team was forbidden to request internal designers and draftsmen, Reinhart had to look for employees by advertisement; for a task that literally inspired any Ford designer. So, among others, Robert McGuffey Thomas and Ray Smith came into the team. Thomas became Reinhart's deputy. The consultant was the designer Raymond H. Dietrich (1904-1980), who had designed bodies for all the classic car manufacturers and had been head of design at Chrysler.

Originally, the car should appear as a convertible with retractable steel roof. However, the cost of this Lockheed- developed system proved to be so high that it would have required US $ 18,000 or almost three times the Cadillac Eldorado. To recoup the cost of the retractable roof, Ford eventually marketed the finished roof system from 1957 to 1959 for the Ford Fairlane 500 Skyline Retractable, after which it was redesigned for the soft top of the following Lincoln and Continental generations and even for the Lincoln Continental from 1961-1969 used this.

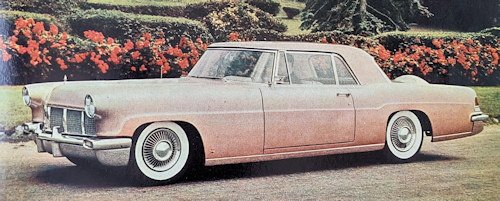

The Continental Mark II was finally published in October 1955 for model year 1956. This was the most expensive in his time in series production car in the United States. The vehicle was prestigious, but brought the company no profit. At each sold Mark II Ford lost about $ 1000. After just over a year, the production of the Mark II was therefore discontinued in 1957; the initially planned expansion of a whole model family failed. Three conventional convertibles with soft top were built, two still exist. One of them was built to factory specifications at Derham and served as a factory prototype. The original Honolulu-blue painted vehicle went to William Ford's family and then to a vice president of Ford, Paul Wagner, sold. The body builder Hess & Eisenhardt (actually specializing in ambulance and funeral vehicles, mainly for Cadillac) made a few other conversions on customer request. A copy was rebuilt, apparently without factory support, in Palm Beach (Florida). Its top is higher than that of the Derham version and it has a metal cover under which it is stored in an open condition.

The production time of the Mark II thus covers 18 months in two model years; Vehicles from 1956 and 1957 differ only slightly from each other and can be distinguished from each other almost only by the vehicle identification number (VIN).

Unfortunately, after a brief market launch, sales were downright catastrophic. By the end of 1955, 1251 Mark II were sold, the rest of the model year 1956 accounted for just 56 vehicles. In the shortened model year 1957 (five months) came again 447 to it. The break-even point was 2500 vehicles. Already in March 1956, the first dealers began to announce discounts. Continental responded to the expected image damage with little success by the dealer network was thinned out.

The failure of Mark II was not due to the brilliant vehicle or organization behind it; it probably even came in the quality of the Rolls-Royce and was far superior in terms of performance. However, the Continental Mark II could not build up a corresponding image. That he was perceived in the public rather as a particularly expensive Lincoln, of course, was also the model on which he oriented himself. This was not changed by a concept that ignored the costs for too long. This resulted in a far too high sale price. Even the more extravagant Cadillac Eldorado Brougham (selling price $ 13,074!), The failure of the Mark II only partially be charged: When this could be ordered in December 1956, the Mark II sales had long collapsed. Incidentally, General Motors was also not happy with its sales success, paid even more money per car on it and undertook similar steps in the third model year as Ford, in order to achieve a nearly realistic selling price.

Ford was still stuck with the Continental brand. Everything else was questioned. So, the next Continental was a completely different car, the Continental Division was combined with Lincoln for a short time to the Lincoln Continental Division, and the new Continental was built on conveyor belts parallel to the Lincoln.

From 1958 to 1960 there were other vehicles of the Continental Division. But they had not the independence of the Mark II cost, also "only" US $ 6135. The Continental Mark III, IV and V (each model year from 1958 to 1960 received its own Roman numeral) were particularly highly equipped, very expensive versions of contemporary Lincoln vehicles. President and General Manager of Lincoln and Continental was Ben D. Mills. One of his specifications was that Lincoln and Continental had to provide more interior space than comparable Cadillac. This goal was achieved not least thanks to the efforts of engineer Earle S. MacPherson.

The fact that Continental was now built at the Wixom (Michigan) plant was not only due to the fact that its own production facilities were needed for the Edsel (initially Edsel ran on Ford and Mercury bands); these plants, in turn, were underutilized with the production of Lincoln and Ford Thunderbird and additional production made sense from this point of view as well. Nevertheless, the conversion was an emergency program with the various problems of the group should be addressed, which went well beyond the Continental debacle. Ultimately, it has Lincoln and Continental helped little.

The construction of the new Lincoln and Continental was unusual - designed for the 1950s - self-supporting. The reason was not only based on the vehicle (the self-supporting construction allows greater rigidity with less weight), but also in the manufacturing technology. Ford and Lincoln in particular had experience with this design; the Zephyr of 1936 was already constructed in this way. Other manufacturers such as Chrysler (Airflow), Nash or Hudson had also already tried it. But never before had it been a Lincoln- sized vehicle or Continental with this design. The problems with a completely new automobile with a construction that had not been tested in this form were considerable. The torsional rigidity of B-pillar bodies was initially quite insufficient; a prototype broke through on a test drive in "hard" terrain even in the rear area. The structural problem was tackled with constant reinforcements. Another cause, inefficient welds and points, could be satisfactorily solved in the fabrication. On the other hand, engineers worked throughout the production period to make the vehicle quieter and smoother. These efforts led on the one hand to reduced performance, but on the other hand also to a massive weight gain which increasingly put the advantage of this design method in question. Along with Lincoln, Continental also switched from 15-inch wheels to 14-inch wheels. If the customer had the Mark II still from its own colour card could select which contained 14 shades (1957: 18, of which 12 metallized), came the Continental of the third generation in the same colours as the Lincoln with whom they together of the assembly lines rolled.

In 1959, Continental introduced a chauffeur-driven limousine ex-factory for the first time. The execution of the small series was transferred to the specialized company Hess & Eisenhardt in Rossmoyne (Ohio) who had already built several show cars and small series vehicles for Cadillac. The basis was the Continental Mark IV Sedan with B-pillar. The conversions included a retractable cutting disc to the driver, even lush interior and on the outside a padded vinyl roof which also enclosed the rear side window and a smaller rear window. The car was only available in black, but there was also a formal sedan, from the factory also little suitable Town Car, called version without cutting disc. It was intended for business people who wanted to work while driving. The production figures were minimal, which was certainly also at the unprecedented prices: the sedan cost US $ 10,230, the Formal Sedan US $ 9208. For the first time, the price of the Mark II was exceeded. Nevertheless, both versions were also offered in 1960, with the adjustments of the Mark V, of course. A total of 83 sedans and 224 sedans were built in both years together.

A Mark IV limousine was built specifically for the visit to Canada by Queen Elizabeth II as Landaulet. A wealthy customer ordered a special version of the Town Sedan with a second radio and air conditioner in the rear as well as in the limousine and had the body painted blue. Also, Queen Juliana of the Netherlands and Elvis Presley.

That the Continental was driven by Lincoln engines; On the one hand, these were the most powerful in the Group. On the other hand, they were on the state of the art with their OHV valve control. An in-house development was excluded for cost reasons. The purchase of another engine would not have made sense or justified this prestige project. More exclusivity was initially achieved by the described selection of the engine and the additional tests. This ended with the Mark III of 1958. The additional effort was in any case unjustifiable; they did not want the Lincoln devalue with quasi "second-class" engines nor stop the production lines with additional interventions on some of the vehicles or make them more complex. The most important reason, however, was that such a measure was not really necessary. The biggest disadvantage of engines was their high fuel consumption also for US conditions this time.

Technical

-

Ford Continental

model year

model

Displacement cm³ (ci)

compression

carburettor

power

1956-1957

Mark II

6040 (368.6)

10.0: 1

Carter; 4x

300 bhp (224 kW) @ 4800 / min

1958

Mark III

7040 (429.6)

10.5: 1

Holley; 4x

375 bhp (280 kW) @ 4800 / min

1959

Mark IV

7040 (429.6)

8.75: 1

Carter; 4x

350 bhp (261 kW) @ 4400 / min

1960

Mark V.

7040 (429.6)

10.1: 1

Carter; 2-

315 bhp (235 kW) @ 4100 / min

For the Mark V, there was an optional version with 400 bhp (298.3 kW). It should have been a version of the same engine with higher compression and other carburettor; already the Mark III made 375 bhp (279.6 kW).