Germany

- Details

- Parent Category: Motor car History

- Category: Germany

Colenta Electromobile GmbH

The Colenta Transporter is a bus similar to the well-known small Suzuki Super Carry. It was built as a two-seat bus with a closed loading area, as a four- or five-seat bus and as a van with flatbed. The specified maximum speed is 65 km / there are two versions based on CMC bodies (China Motor Corporation) whose models are Mitsubishi's license replicas. The smaller one has as base the Minicab and the larger the Mitsubishi Varica. The second body variant is still used in the Indian model Premier Sigma.

It was built in the early 1990s, a few hundred copies of the German company Colenta (Colenta Electromobile GmbH) to the electric car. Of these, only a few collectibles are still in operation. One problem is the procurement of spare parts, especially for the mechanical parts. There are variants with 90 volts (15 × 6V) and 96 volts (16 × 6V). The empty weight including battery is 1,190 kg, and the payload is 450 kg. The maximum speed is 65km/h, the range is up to 80 km, and the main areas of operation are North Sea islands such as Wangerooge

The Colentas are very differently equipped. There are some with internal electronic chargers, with external charger, with battery management system (Badicheq by Mentzer) etc.

- Details

- Parent Category: Motor car History

- Category: Germany

Hauser GmbH

Automotive manufacturer Eichenau Munich Germany from 1997 on

The Hauser GmbH is a German company and former manufacturers of automobiles from the 1990s. The brand name was Hauser.

History

The Swiss Jean-Claude Hauser, previously at BBC Brown Boveri and BMW Motorsport GmbH was active, founded the company 12 May 1997. The headquarters was initially located at Kreuzeckweg 5 in Eichenau. 1999 began the production of automobiles. In 2006, the seat was the Ohlauer Strafe 67 in Munich as of 2012 production ended.

Hauser H 1

The H 1 is a roadster in the style of the Lotus Seven with front engine and rear-wheel drive. The body consists of plastic, the specially designed space frame made of steel. The axles are from Daimler AG. Front independent suspension with triangular control arms and coil springs is used, behind is a multi-link axle installed with coil springs. The vehicle has at least from 2009 front and rear curve stabilizers. For the drive ensure six-cylinder engines from BMW. to select initially were engines with 2494 cc 2793 cc, 3152 cc and 3201 cc Displacement. The latter engine made 321 hp. The maximum speed of the strongest model was specified 241 km / h and the empty weight of 900 kg.

The new price changed over the years from over 65,900 euros in the model years 2003 to 2006 to 67,000 euros in the model year 2007.

In its last version, occupying from 2009 to 2011, the H1 was only offered with a BMW six-cylinder engine with 2997 cc capacity. It is a four-valve with two overhead camshafts and intake manifold injection. In this form, it delivers 200 kW (272 hp) at 6700 rpm. The maximum torque of 320 Nm is achieved between 2750 and 3000 / min. The maximum speed is 230 km / h. The acceleration from 0 to 100 km / h takes place in 5.1 seconds and the consumption is given as 7 to 13 l / 100 km. The power is transmitted by means of a five-speed gearbox. There are ventilated disc brakes all around; the handbrake acts on the rear wheels. The factory fitted 17-inch wheels with 215/40 R front and 265/40 R rear tires. The wheelbase is 2450 mm, the length 3850 mm, the width 1770 mm, the height 1040 mm and the weight 915 kg.

- Details

- Parent Category: Motor car History

- Category: Germany

Hannoversche Waggonfabrik AG (HAWA)

Automotive manufacturer Hanover - Linden, Germany from 1921 to 1926

HAWA (Hannoversche Waggonfabrik AG) was a German Automotive manufacturer in the 1920s.

History

The Hanover Waggon Factory AG (HAWA) in Hanover - Linden produced from 1898 to 1933 railway cars, tram cars, automobiles, combat aircraft and agricultural machinery.

AG. The company was founded on February 6, 1898 in Linden near Hannover as a Hanoverian woodworking and wagon factories (formerly Max Menzel and Buschbaum & Holland)

The object of the company was the operation of a wagon-building, wagon-building and wood-working factory, in particular for the production and exploitation of all types of railways, tram and other wagons, and the manufacture and sale of all items necessary for the equipment of railway and other means of transport. In 1904 the company name was changed to Hannoversche Waggonfabrik AG and in 1925 to Hannoversche Waggonfabrik AG (Hawa).

The artillery Rademacher Heinrich Christian Oelschläger operated since 1830 in Linden the Rademacher craft. His enterprising son Friedrich Oelschläger received permission in 1857 to manufacture carriage cars. In addition, he made individual parts, such as wheels, drawbars, axles and carried out repair work.

The business was transferred to Wilhelm Buschbaum, who found a partner with the master carpenter Fritz Holland, who provided for an expansion of the construction program and enlargements of the factories. When there was a great need for railway vehicles, the company switched to wagon-building. In 1891 they received the first wagon order for 25 horse trolleys for the Hanover tram. After further tram orders for Braunschweig and Stadthagen followed 1895 the first order over passenger and freight cars for the railway Börßum - Hornburg.

After Max Menzel had secured the financial support of the Hannoversche Bankhaus Ephraim Meyer & Sohn, he joined the company Buschbaum & Holland, and after lengthy negotiations eventually became the public company founded. The foundation fell into a period of stagnation, six wagon factories were founded during the year. Unfavourable terms of payment and depressed prices delayed the recovery despite abundant orders. After the company had managed to obtain significant orders from abroad, mostly for tram cars, which they have in common with the AEG these difficulties were overcome.

The HAWA had a large production range from iron garden pavilions on tractors, threshing machines, electric cars to road and rail cars and aircraft and gliders. From 1921 to 1926, the company produced the Hawa 40 Volt electric compact car in both a passenger car and a van version.

The Hawa 40 Volt electric small car was produced in the first half of the 1920s by the Hanoverian wagon factory (Hawa) in small quantities electric vehicle for road traffic. about 2000 copies of the small Cyclecar, which was powered by a 40-volt battery electric motor The body was made of beech wood covered with plywood. As a passenger car, this was built as a " tandem " two-seater, but also as a small van electric delivery truck Type Em 3 L with a small 0.1 ton payload. The vehicle weighing 320 kg with a wheelbase of 156.4 cm and a track width of 89 cm, the vehicle was 242.3 cm long and 115 cm wide It was distributed by the German automobile factories,(G.D.A) in Berlin until 1926.

- Details

- Parent Category: Motor car History

- Category: Germany

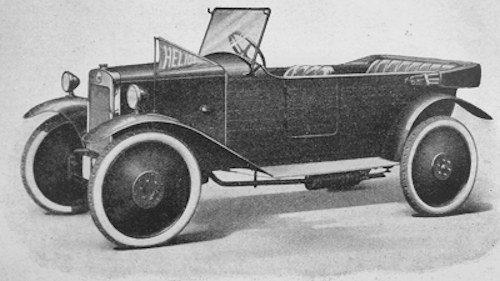

Helios-Automobilbau AG

Automotive manufacturer Cologne - Ehrenfeld Germany from 1903 to 1929

The Helios AG an electric light and telegraph plant was founded in 1882, And also built cars and commercial vehicles from 1903 to 1906 and later again in the 1920s.

History

The Helios AG companies from the pioneering days of Electrical Engineering. The company headquarters and production site were the then industrial city of Ehrenfeld, which was incorporated into Cologne in 1888.

Helios acquired in 1903 from the motor truck factory Rudolf Hagen & Cie. GmbH from Cologne patents and manufacturing facilities for passenger cars until 1909.Again later in the 1920s car were built.

The former administration building Helioshaus, the former production halls as well as the former company landmark, a 44-meter-high lighthouse for experiments and demonstrations.

In 1903 A car model with two-cylinder engine and 10 hp and two models with four-cylinder engine and 20 or 40 hp were produced. In addition, trucks and electric buses and trams with electric drives appeared they were built by 1906, the Type SP trucks with 2 or 4-cylinder engines between 10,20 and 40 hp were being produced Licenses to build vehicles were granted to England and France. 1906 ended the first motor vehicle production.

in 1923, that Delfosse and Kölner Industriewerke GmbH founded Helios Automobilbau AG After the Cologne-based industrialist and automobile pioneer Arthur Delfosse had taken over parts of the electrical company Helios, they began to produce automobiles under the Helios brand.

The technical direction was taken over by his son Curt Delfosse. Helios developed and built a small cars with water cooling, cardan gear, solid chassis frame types H2 and H3 were created with two seats and a two-cylinder boxer engine with 972 cc four-stroke displacement, whose power was transmitted via a cardan shaft to the rear wheels. The Small cars of only 3 meters overall length with 8 to 9 hp engine power and a weight of 350-380 kg.Maximum speed: depending on the engine 50 or 60 km per hour the fuel consumption: depending on the engine 3 or 3.5 kg per 100 km.

The driver and one or two passengers sat in tandem. The automobiles were advertised as cheapest German quality cars to buy at of 2950 marks. By 1928 vehicles of the Helios types H4 with 16 hp and H1 or H1D with 36 or 32 hp All parts are interchangeable.

- Details

- Parent Category: Motor car History

- Category: Germany

VEB Sachsenring

Automotive manufacturer Zwickau, Germany from 1955 to 1969.

HQM Sachsenring GmbH is a Zwickau-based company that supplies chassis and body parts to the automotive industry. The company was named after the Sachsenring race track. Founded as VEB (Volkswagen Betrieb) Sachsenring a Publicly Owned Enterprise after the end of World War II, Sachsenring was one of the only manufacturers of vehicles in the German Democratic Republic, its most famous product being the Trabant along with Commercial vehicles as IFA.

The history of the Sachsenring goes back directly to the plants of Horch (famous for luxury cars) and Audi in Zwickau. Horch was expropriated along with the rest of Auto Union in June 1948 after a referendum. In the same year, the plant was reopened as VEB HORCH Kfz- und Motorenwerke Zwickau as a company in the Vehicle Construction Industry Association (IFA). Initially, the H3 truck and the RS01 tractor were manufactured here. In 1950 production of the newly developed IFA H3A began, for which a diesel engine was used that was also produced in Zwickau.

The Horch factory tried to maintain the tradition of luxury limousines with the P 240 "Sachsenring" (known as Horch "Sachsenring"). The name of the vehicle was transferred to the plant in 1957, which from then on was called VEB Sachsenring Kfz- und Motorenwerk Zwickau. At the same time, the forerunner of the Trabant, the AWZ P 70, was produced at the VEB Automobilwerk Zwickau (AWZ), on which initial experience with body parts made of Duroplast could be gained.

By 1958 to form VEB Sachsenring Automobile Zwickau. Truck production was handed over to the “Ernst Grube” motor vehicle factory in Werdau, with truck diesel engine production remaining in Zwickau until 1965.The new Trabant 601 in 1963 was the last successful new development by the Sachsenring development department. In the 1970s and 1980s, the Trabant was built almost unchanged.

It was not until 1984 that there were signs of progress, which was actually put into practice: as part of a comprehensive cooperation agreement with Volkswagen, the IFA had acquired the license to build the VW Polo engine, which was mass produced in the Barkas works from 1988. Following the reunification of Germany in 1990, Sachsenring transitioned from a government-owned company under a centrally-planned economy to a private corporation in a free market economy. As from 1993 as FES GmbH Fahrzeugentwicklung Sachsen. The plant was sold together with the rights to the name, to the Rittinghaus brothers from Hemer, who wanted to establish the company as an automotive supplier under the name Sachsenring Automobiltechnik GmbH. The company quickly developed into a model company in the new federal states. In 1996 it was converted into a public limited.

Both Sachsenring Fahrzeugtechnik GmbH and Sachsenring AG filed for insolvency on May 30, 2002. After three years in bankruptcy, Sachsenring AG was purchased in February, 2006 by Härterei und Qualitätsmanagement GmbH (HQM) of Leipzig. Formerly the dominant and only major automaker in East Germany, Sachsenring has since departed from making motor vehicles. At the end of August 2014, production ceased in the remaining Mechanical Production division.

Models

1954-1959 P24 Marketed as the Horch P 240 “Sachsenring” until 1957. Engine: in-line six-cylinder four-stroke engine (2,407 cm³, 80 hp), total length: 4,730 mm, mass: 1,480 kg, wheelbase: 2,800 mm, top speed: 140 km/h

1955-1959 P70 "Zwickau “Produced by AWZ as "AWZ P 70 'Zwickau'" until 1958. The P 70 was one of the first production cars with a plastic body. The floor assembly was identical to that of the DKW F 8. Production ended in 1959 in favour of the Trabant.

1957-1962 Trabant(P50) Produced until 1958 as "AWZ P 50 'Trabant'". The P 50 was to be the first mass-produced car in the GDR.

1962-1965 Trabant 600(P60) Identical in construction to the P 50, but with a larger engine (from 500 cm³/18 hp to 600 cm³/23 hp). The station wagon version was produced for two more years until the body of the "Trabant 601 universal" was finished.

1969 representative Following an order from the NVA, five representative vehicles based on the P 240 with a contemporary body were built in 1969 to mark the 20th anniversary of the GDR.

1964-1990 Trabant 601(P601) Floor assembly and engine identical to the P 60, but with a new trapezoidal body, but with old doors and front fenders. Later increase in performance (e.g., crankshaft with needle bearings) to 26 hp.

1957-1958 H3SThe H3S was a revision of the Horch H3A, making it the first truck that Sachsenring-Werke produced.

1959-1960 S4000 S4000-1The "S4000" (S for Sachsenring) had a payload of 4.0 t. It used the same cab as the H3A/H3S and so resembled it in appearance. In 1960, production was relocated to the “Ernst Grube” motor vehicle plant in Werdau. Here the S4000 was further developed into the W50 (W for Werdau). In 1965 the entire production was relocated from Werdau to Ludwigsfelde near Berlin.

1990-1991 Trabant 1.1Sales designation "IFA Trabant 1.1". Body almost identical to the P 601, but with a new bonnet made of sheet steel. Technical improvements to the chassis also due to the use of Volkswagen 's four-stroke licensed engine.