USA

- Details

- Parent Category: Motor car History

- Category: USA

Eshelman

Eshelman was a marque of small American automobiles and other vehicles and implements including motor scooters, garden tractors, pleasure boats, aircraft, golf carts, snowplows, trailers, mail-delivery vehicles and more. The Cheston L. Eshelman Company was incorporated on January 19, 1942, and was based on the sixth floor of an industrial building at 109 Light Street in Baltimore, Maryland, with aircraft production facilities located in Dundalk, Maryland. The company president was Cheston Lee Eshelman, the first vice-president was Sidney S. Zell (July 30, 1900 - July, 1978), and the first treasurer was Frank K. Kris (January 4, 1910 - March, 1981).

The Eshelman company began production of commercial light aircraft in Dundalk after World War II, but was best known toward mid-century for its inexpensive light garden tractors and similar machines (including the Kulti-Mower) which were widely promoted in small advertisements in the back pages of mechanical and scientific magazines.

By 1955 a second, larger model was added to the Eshelman line, a basic six-horsepower open car for two passengers also named the "Adult Sport Car". These ASCs were 64 inches (1,600 mm) long, 36 inches (910 mm) wide and 32 inches (810 mm) in height and were powered by an air-cooled rope-started Briggs & Stratton #14 engine (electric starting was optional) that permitted a top speed of 30 mph (48 km/h) and a 70 mpg‑US (3.4 L/100 km; 84 mpg‑imp) fuel consumption rate. Major ASC mechanical differences included 4.50x6 pneumatic tires with four-wheel cable-operated scrub brakes, a foot throttle, and a pedal-operated parking brake. Extra-cost options included a lawn sweeper ($39.95) and a hauling cart ($79.95). The Adult Sport Car was 40 inches wide and was equipped with headlamps and taillamps powered by a separate battery that needed occasional charging, as there was no generator.

The following year saw a minor restyling on both models including an opening hood, cut-down sides for easier entry and exit, and fully opened rear wheel wells. A utility version of this car was offered for use on golf courses (and advertised as providing "36 holes per gallon"). Also from 1956 the smaller models were powered by Briggs and Stratton aluminum-block engines; the Model 6B engine of 2.25 horsepower in the standard series and the Model 8B engine of 2.75 horsepower in the deluxe cars.

But on Friday, February 10, 1956, a massive fire consumed the Eshelman factory. Two hundred firefighters and two fireboats helped to extinguish the blaze, and the fire resulted in $500,000 in damage.

At about that time the city of Baltimore began taxing manufacturing inventories and equipment, and so in February 1957 Cheston Eshelman signed a ten-year contract with the Charles D. Briddell Company, makers of cutlery, to build Eshelman cars and other vehicles at its Crisfield, Maryland, facility. A decision was also made to upgrade the cars, and Eshelman introduced several versions of the new and more-streetworthy two-passenger "Sportabout", a 675-pound enclosed model of the Adult Sport Car with a Model 23 Briggs and Stratton 8.4 horsepower single-cylinder engine. The 72-inch-long Eshelman Sportabout had more appurtenances, including electric starting and windshield wiper, reverse gear, directional signals, a 60-inch tall aluminum top, doors, spring suspension, foam upholstery, and a horn. All Sportabouts were painted red with silver doors and were shipped to buyers' addresses in wooden crates.Television star Bob Cummings (The Bob Cummings Show) became a spokesman for the Eshelman company in newspaper and magazine ads, and often featured Child Sport Cars on his programs. A new battery-powered child's car, the Model 200, was added, and thousands of the company's blue Mailster mail-delivery vehicles were seen on the streets of America, closely resembling the very similar Cushman mail carrier design.

By 1959 the Eshelman company, now renamed the Eshelman Motors Corporation, introduced a trio of much larger $1,395 two-cylinder air-cooled closed models, the fiberglass-bodied Models 902 delivery vehicle, 903 coupe and 904 pickup truck, all advertised as seating three passengers abreast. However, according to reports only about twelve or so were produced.

Eshelman then turned to buying new fleet-model Chevrolet Corvairs in quantity, which were re-trimmed and re-badged with special gold-colored Eshelman insignia and other appearance changes and marketed to the public as "Eshelman Golden Eagles". When General Motors learned of this operation, it ordered Eshelman Motors to cease and desist, but Eshelman continued to market the appearance package for those who wished to apply them to their personal cars.

Concurrently, Cheston Eshelman moved to Miami, Florida, and worked on marketing his patented "crash absorber," a pioneering 15 mph (24 km/h) energy-absorbing front bumper fashioned from a vehicle's spare tire. He often demonstrated the bumper by ramming his own car into retaining walls.

In 1967, Eshelman produced the final Eshelman Golden Eagle Safety Cars based on new 1967 Chevrolets, all equipped with front "crash absorbers" and sold through several used-car agencies. This marked the end of Eshelman's automotive efforts and other operations, but he continued to invent and patent his ideas for decades. He died on November 7, 2004, in Hialeah, Florida.

- Details

- Parent Category: Motor car History

- Category: USA

Duryea Motor Company

The Duryea Motor Wagon Company, established in 1895 in Springfield, Massachusetts and Reading in February 1900. By 1901, Duryea and Sternbergh incorporated the Duryea Power Company and was the first American firm to build gasoline automobiles.

History

Founded by Charles Duryea and his brother Frank, the company built the Duryea Motor Wagon, a one-cylinder "Ladies Phaeton", first demonstrated on September 21, 1893, in Springfield, Massachusetts, on Taylor Street in Metro Center. It is considered the first successful gas-engine vehicle built in the U.S.

In 1895, a second Duryea (built in 1894), driven by Frank, won the Chicago Times Herald race in Chicago on a snowy Thanksgiving day. He travelled 54 miles (87 km) at an average 7.5 mph (12 km/h), marking the first U.S. auto race in which any entrants finished. That same year, the brothers began commercial production, with thirteen cars sold by the end of 1896. Their first ten production vehicles were the first automobiles sold in the United States. Banking on the idea that future racing successes would propel their market share, The brothers entered two vehicles in Britain's London to Brighton Car Run. Frank placed first and beat out the nearest competition by 75 minutes. As well in 1896, a Duryea motorcar had the unfortunate distinction of being in the world's first automobile accident, in New York City, when its driver struck a bicyclist and broke his leg. The driver spent the night in jail.

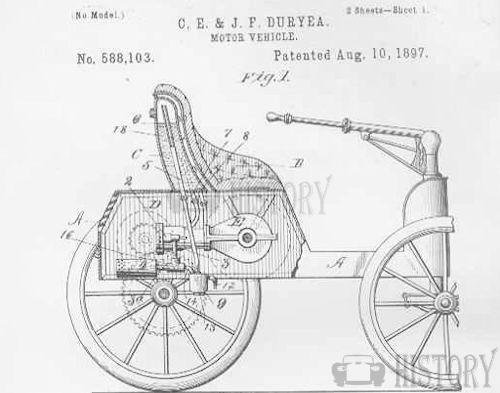

1897 Duryea Motor car patent

The brothers went their separate ways by the end of the century, over a dispute for financing that would have required moving the company to Detroit. Frank helped produce the Stevens-Duryea (at gun maker Stevens) until 1927, while Charles produced Duryea vehicles as late as 1917. Based in Reading, Pennsylvania, it was not uncommon for residents to see him motoring a brand new automobile from City Park out to Mount Penn, managing the switchback road as a final test of durability and refinement.

Charles Duryea moved to Reading in February 1900. By 1901, Duryea and Sternbergh incorporated the Duryea Power Company

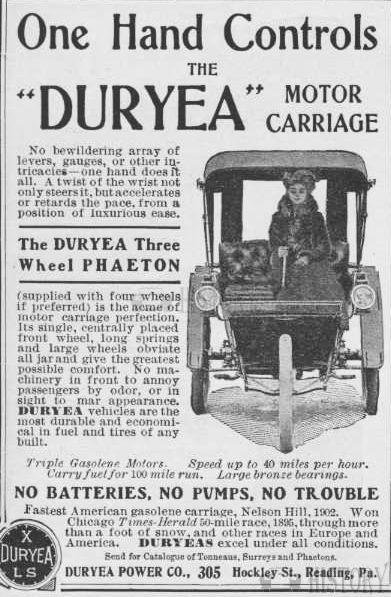

Duryea 1902 Three wheel Phaeton car

"for the manufacture of iron, steel, bath, any metal or wood or both, including automobiles, motors, propellers, and part of either." By March 1902, after overcoming difficulties procuring factory space, and a devastating flood of the Schuylkill River, Duryea was manufacturing one three-wheel, three-cylinder, gasoline powered automobile each week. Most buyers were doctors, who enjoyed the power, reliability, and heady 20 mile-an-hour top speed of his vehicles.

1904 Duryea Bennett race

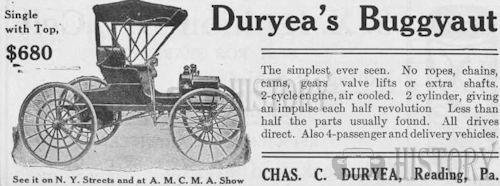

By 1905, Duryea's fifty workers were manufacturing sixty cars a year, including the four-wheel Phaeton, which soon sold for $1,600. Duryea's automobiles were a success, but a fight among the company's partners led to collapse of the business in 1907. Undaunted, Charles Duryea designed a new automobile with significant design innovations, including a two-cylinder, air-cooled engine, which he named the "Buggyaut." Manufactured in a garage at 32 Carpenter St., the Buggyaut was an inexpensive auto with large wheels designed for rural markets and unpaved roads. To make the car affordable, Duryea introduced a simple body design, mounted on the side bars of the chassis, in usual buggy fashion, that made the Buggyaut light and easy riding. The two-passenger model, complete with top, sold for only $700, but the Buggyaut never achieved the success that he had envisioned. In 1914, Duryea closed the garage and left Reading.

1906 Duryea car

In 1916, eight years after Henry Ford introduced his Model T, Duryea made another attempt to produce his own "car for the people." With financing from Keyser Fry of Reading, he created the Duryea GEM, a cross between an automobile and a motorcycle, with a newly designed engine and suspension. Advertised as the "Biggest Idea in the History of the Motor Car and the Last Word in Automobile Construction," the Duryea GEM combined the comfort and stability of an automobile with the simplicity, handling, and economy of a motorcycle. It was also extremely affordable, costing only $250 and boasting an impressive 65 miles of driving per gallon of gasoline. Once again, however, lack of funding forced Duryea to drop the project, with only six being thought to have been built. The GEM was the last automobile built by Charles Duryea.

Simple Duryea Buggyaut car

Although Charles did discuss with Frank Duryea the building of the first commercially successful American automobile, Frank was the actual builder during their collaboration. He did correspond with his brother Charles regarding what did and did not work in the design. Charles left Springfield in 1892 before construction began. This was documented in transcripts during the Selden Patent trial.

Boyertown Museum of Historic Vehicles in Boyertown, Pennsylvania hosts an annual Duryea Day Antique and Classic Car Show, which features an extensive collection of automobiles manufactured in southeastern Pennsylvania in the early 20th century. Since 1951, the SCCA has sponsored a biannual "Duryea Hillclimb" race in Reading which traces Charles' original test route.

- Details

- Parent Category: Motor car History

- Category: USA

Dort Motor Car Company

American Automotive manufacturer Flint, Michigan .United States from 1915 to 1924

The Dort was an automobile built by the Dort Motor Car Company of Flint, Michigan from 1915–1924. Dort used Lycoming built engines to power their vehicles.

Dort Motor Car traced its history back to its founding as the Flint Road Cart Company in 1884 by William Crapo Durant and Josiah Dallas Dort, who sold wagons, built by local suppliers for $8 apiece. In 1900, the company, which by now was making 50,000 wagons, carts, and carriages annually, changed its name to Durant-Dort Carriage Company.

Dort was a Director and Vice President of Chevrolet in 1912; in 1913 Dort stepped down and by 1915 he and Durant cut their business ties.

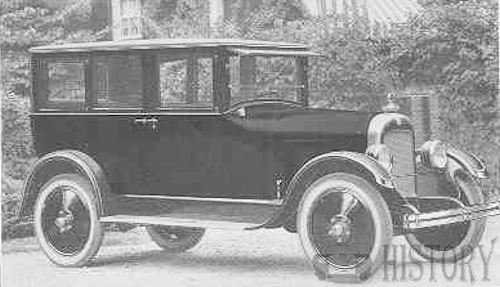

Dort six touring 1924

By 1917, Dort was offering four models: a closed sedan at $1,065, a convertible sedan at $815, a five-place open tourer at $695, and a Fleur-de-Lys roadster at $695. well equiped with optional speedometer for $495.

1917 Dort engine view

Dort continued manufacturing cars until 1924,with new lower sitting bodies and oil cushion engines but with the mounting price of development and distribution of the vehicles made it impossible to compete in the automotive markets of the 1920s. Josiah Dallas Dort’s death in 1923 sealed the fate of Dort Motors.

Dort six sedan 1924 115" wheelbase

- Details

- Parent Category: Motor car History

- Category: USA

Doble Steam Motors Co

Automotive manufacturer of United States from 1909 to 1931.

Production Waltham, Massachusetts .Detroit, Michigan. Emeryville, California

Emeryville, California Factory

The Doble steam Car was an American steam car maker from 1909-1931. Their latter models of steam car, with fast firing boiler and electric start, were considered the pinnacle of steam car development. The term "Doble steam car" comprises any of several makes of steam-powered automobile in the early 20th century, including Doble Detroit, Doble Steam Car, and Doble Automobile, severally called a "Doble" because of their founding or association with Abner Doble.

History

There were four Doble brothers: Abner, William, John, and Warren. Their father became wealthy, patenting the Doble Pelton wheel. All were at one time associated with the automobile company, with Abner, John, and Warren as the leading lights.

Abner Doble built his first steam car between 1906 and 1909 while still in high school, with the assistance of his brothers. It was based on components salvaged from a wrecked White Motor Company steamer, driving a new engine of the Doble brothers' own design. It did not run particularly well, but it inspired the brothers to build two more prototypes in the following years. Abner moved to Massachusetts in 1910 to attend MIT, but dropped out after just one semester to work with his brothers on their steam cars.

Their third prototype, the Model B, led Abner to file patents for the innovations incorporated in it which included a steam condenser which enabled the water supply to last for as much as 1,500 miles (2,400 km), instead of the typical steam car's 20–50 miles (30–80 km). The Model B also protected the interior of the boiler from the common steam vehicle nuisances of corrosion and scale by mixing engine oil with feedwater.

While the Model B did not possess the convenience of an internal combustion engined vehicle, it attracted the attention of contemporary automobile trade magazines with the improvements it displayed over previous steam cars. Apart from its slow starting time, the Model B was virtually silent compared to contemporary gasoline engines. It also possessed no clutch or transmission, which were superfluous due to the substantial torque produced by steam engines from 0 rpm. Most noticeably, the Model B could accelerate from 0 to 60 mph (0 to 97 km/h) in just 15 seconds , whereas a Ford Model T of the period took 40 seconds to reach its top speed of 40–50 mph (64–80 km/h).

1918 Doble Steam engine internal view

The Detroit

In 1915 Abner drove a Model B from Massachusetts to Detroit to seek investment. He managed to acquire the sum of $200,000, which he used to set up the General Engineering Company in Detroit. The Doble brothers at once began work on their Model C (also known as the Doble Detroit), which was planned to extend and expand upon the innovations pioneered in the Model B.

The Doble Detroit incorporated key ignition, doing away with the need for manual ignition of the boiler system. John Doble also constructed a flash boiler with rectangular casing in which atomized kerosene fuel was ignited with a spark plug, in a carburetor-type venturi and used forced draft provided by an electrically driven fan. This rapidly heated the feedwater contained in vertical grids of tubes welded to horizontal headers. The steam-raising part of the boiler was partitioned off by a wall of heat-resisting material jacketed with planished steel from a smaller compartment in which were similar grids of tubes for feedwater heating. There seem to have been at least two versions of this boiler, the first with the burner and combustion chamber at the bottom, the other with them at the top of the casing; we can already see the thinking that led to the subsequent counterflow monotube boiler arrangement. Boiler operation was fully electro-mechanically automated: the bottom of the boiler housed a metal tray with a row of quartz rods. As heat increased, the tray expanded, pushing the rods forward and shutting off the burner. As the system cooled, the quartz rods contracted, engaging the burner.

The Detroit could start from cold in as little as 90 seconds. A two-cylinder double-acting uniflow engine was mounted under the floor driving the back axle; double slide valves were driven by Joy's valve gear. The car had only four controls — a steering wheel, a brake pedal, a trip pedal for variable cut-off and reversing, and a foot-operated throttle. The layout of the chassis put the boiler at the front end of the car under the hood, the engine and the rear axle forming an integrated unit. The even weight distribution and low center of gravity contributed much to the ride and handling of all Doble cars.

These improvements promised a steam car that would at last provide virtually all of the convenience associated with a conventional automobile, but with higher speed, simpler controls, and what was a virtually noiseless power plant. The only defect sometimes noted throughout the Doble car era was less than perfect braking, which was common in automobiles of all types before 1930. Typically, a car of 1920s only had two rear-mounted mechanical drum brakes, although those fitted to Dobles were of larger than usual proportions. Dobles achieved reliability by eliminating most of the mechanical items that tended to malfunction in conventional automobiles: they had no clutch, no transmission, no distributor, no points. Later Doble steam cars often achieved several hundred thousand miles of use before a major mechanical service was necessary

1918 Doble Steam Touring "Double Seven"

The Doble Detroit caused a sensation at the 1917 New York Motor Show and over 5000 deposits were received for the car, with deliveries scheduled to begin in early 1918. However, the Doble brothers had not entirely worked out various design and manufacturing issues, and although the car received good notices and several thousand advance orders were placed, very few were actually built, estimates ranging from 11 to as many as 80. Abner Doble blamed his company's production failure on the steel shortages caused by World War I, but the Doble Detroit was mechanically unsatisfactory. Those few customers who had received completed cars complained that they were sluggish and unpredictable, some even reversing when they should have gone forward. In addition, the Doble brothers were divided by Abner's insistence on taking credit for the company's technical achievements, and John Doble ended up suing Abner for patent infringement, whereupon Abner left Detroit for California. They used 135-inch (3,400 mm) wheelbases.

Steam powered tanks

During WW1 Doble's Detroit steam motors were used in two prototype tanks. One was the Holt Manufacturing Company steam powered tank. This tank underwent trials in February 1918, but no further models were made. The other was a Steam Tank project by the Corps of Engineers. The Corp had created a successful flame-thrower in November 1917 and decided to mount it on a tank. Funding for the project was made by the Endicott and Johnson Shoe Company. The tank was similar in design to British heavy tanks of the period. It weighed 50-tons and was powered by two Doble steam engines.

The Model D

The outcome was a complete redesign, the Model D of 1922. The uniflow engine, perceived as the root of the troubles with the Doble Detroit, gave place to a two-cylinder compound type, still with Joy's valve gear, but with piston valves. Another crucial development was a coiled monotube once-through vertically-mounted cylindrical boiler following the thinking behind the later version of the Detroit boiler, the most distinctive feature of which was the placing of the burner at the top of the boiler. This plus drastic insulation was meant to cause the hot gases to reside within the boiler casing for an optimum length of time giving up the maximum amount of heat to the feedwater. There was a forced draft burner at the top of the boiler and an exhaust flue at the bottom. The venturi was placed horizontally at the top of the vertical boiler barrel and oriented in such a way as to avoid direct contact with the monotube while inducing a swirl motion to the gases. It was thus a counterflow design with water entering the lower end of the coiled monotube and progressing upward toward the burner, which meant that the hottest gases gave superheat to the steam at the top of the coil whilst the cooler gases preheated oncoming the feedwater at the bottom. The distinctive hand operated "miniature steering wheel” rotating a throttle control rod that passed down the middle of the steering column can be observed in D2 which still exists (in the UK) at the present time. Photographic evidence shows that D1 retained the foot throttle pedal, so when the wheel throttle control was first applied is not clear. The latter probably gave more precise adjustment.

No more than five of the D model appear to have been built, if that. It is said that the two-cylinder compound engine sometimes gave difficulty in starting.

Mid 1920s Doble Steam Car engine and Chassis

The Model E

By 1922, the model E had been developed; this could be said to be the "classic" Doble, of which the most examples have survived. The initial monotube boiler design was perfected into the "American" type. This produced steam at a pressure of 750 psi (52 bar) and a temperature of 750 °F (400 °C). The tubing was formed from seamless cold drawn steel 575 ft 9 in (175 m) in total length, measuring 22 inches (560 mm) in diameter by 33 inches (840 mm) in height when coiled and assembled. The boiler was cold water tested to a pressure of 7,000 psi (480 bar). Two 2-cylinder compound cylinder blocks were in effect placed back-to-back as the basis for a 4-cylinder Woolf compound unit with high-pressure cylinders placed on the outside. A piston valve incorporating transfer ports was fitted between each high-pressure and low-pressure cylinder in an arrangement similar to Vauclain's balanced compound system used on a number of railway locomotives around 1900. Stephenson's valve gear replaced the previous Joy motion. This engine was used on all vehicles developed thereafter. Again, the car neither possessed nor needed a clutch or transmission, and due to the engine being integrated directly into the rear axle, it did not need a drive shaft either. Like all steam vehicles it could burn a variety of liquid fuels with a minimum of modification and was a noticeably clean running vehicle, its fuel being burned at high temperatures and low pressures, which produced very low pollution. Price ranged from $8,800 to $11,200 in 1923. The Model E ran on a 142-inch (3,600 mm) wheelbase. Twenty-four E's were made between 1922 and 1925 with a variety of body types from roadsters to limousines. Owners included Howard Hughes and the Maharajah of Bharatpur. One of the Hughes cars, a roadster engine number 20, is currently owned by Jay Leno. Abner Doble owned the last one - number 24.

The E cars still known be in existence are 9 (at the Ford museum), 10 (in the UK), 11 (in Australia), 13 (in New Zealand), 14, 17, 18, 19, 20, 22 (in the UK),23, and 24. Number 24 was acquired by McCulloch in the development of the Paxton steam car. Those known to be scrapped were 4, 5, 7, 15, and 16.

The Model F

The main new feature was the boiler which formed the basis of later developments from 1930 onwards after the Doble company folded. Various other refinements were applied to individual cars such as a steam driven water feed pump. Seven model Fs were made, one of which was owned by Abner Doble's wife. They were car numbers 30 to 35, and 39. One of these, number 35, was a chassis only and sold to Oscar Henschel in Germany. Henschel's car was used by Hermann Göring and believed destroyed during the war. The car bodies were otherwise sedans or phaetons. The last F car number 39 was owned by Warren Doble. Engine number 32 was fitted into a Buick.

F30 and F34 still exist. The F30 is thought to be an E model engine and chassis. F34 in existence is said to be based on a Buick Series 60.

Engine Numbers

Doble numbered all his engines sequentially:

- Numbers 1 to 24 were Model E's

- Numbers 25, 28, 29, 36 to 38 were Model H engines for buses. The later three were used for a locomotive, power plant, and truck.

- Numbers 26, 27 were Model G engines for the Detroit Motorbus Company

- Numbers 30-35, and 39 were Model F's

- Number 33 may have been used twice, once for the Model F and once for the A & G Price model H bus engine.

Typical performance

The 1924 model Doble Series E steam car could run for 1,500 miles (2,400 km) before its 24-gallon water tank needed to be refilled; even in freezing weather, it could be started from cold and move off within 30 seconds, and once fully warmed could be relied upon to reach speeds in excess of 90 miles per hour (140 km/h). In recent years Doble cars have been run at speeds approaching 120 mph (190 km/h), this without the benefits of streamlining, and a stripped down version of the Series E accelerated from 0 - 75 mph (121 km/h) in 10 seconds. Its fuel consumption, burning a variety of fuels (often kerosene), was competitive with automobiles of the day, and its ability to run in eerie silence apart from wind noise gave it a distinct edge. At 70 mph (110 km/h), there was little noticeable vibration, with the engine turning at around 900 rpm.

Contemporary Doble advertisements mentioned the lightness of the engine, which would lead customers to compare it favorably with heavier gasoline engines, but "engine" in a steam car usually refers solely to the expander unit, and does not take into account the complete power plant including boiler and ancillary equipment; on the other hand clutch and gearbox were not needed. Even so, the overall weight of a Series E was in excess of 5000 pounds.

Doble Steam Motors Company

The first model E was sold in 1924, and Doble Steam Motors continued to manufacture steam-powered cars for the next seven years. In 1924 the State of California learned that Abner had helped to sell stock illegally in a desperate bid to raise money for the company, and though Abner was eventually acquitted on a technicality, the company folded during the ensuing legal struggle.

For all their innovations, Doble cars were hindered by two significant problems. The first was the price: the chassis alone sold for $9500, and adding a body virtually doubled that figure, making the car a luxury item in the 1920s. In 1922 the brothers had begun work on a lower cost model, projected to sell for less than $2000. This was named the Simplex, and was to be powered by four uniflow single-acting cylinders. One prototype is known to have been constructed, but the car never approached production stage. The other problem was Abner Doble himself, who was said to be such a perfectionist that he was seldom willing to stop tinkering and actually release an automobile for sale.

Doble made two further steam engines, designated models G and H respectively. These were larger units and used experimentally in several buses. The first were tested in 1926 by International Harvester, using a Doble Model G engine, and the Detroit Motorbus Co, in a double decker, with a Doble Model H engine. A second Detroit bus had a Doble steam engine added in 1927 and at least one of them covered some 32,000 miles. In 1929 a Doble Model H was installed in a Yellow Coach for General Motors. This was followed by another Model F in a Fageol bus.

The company eventually went out of business in April 1931. The total number of cars built up to that date is difficult to determine; but as the numbers were consecutive, whatever the model, even with the solitary known Simplex, it seems unlikely that more than 32 were built from 1922.

Later 1925 Doble Steamer car

- Details

- Parent Category: Motor car History

- Category: USA

Diamond T

The Diamond T Company was an American automobile and truck manufacturer in the 20th century.

History

The Diamond T Motor Car Company was founded in Chicago in 1905 by C. A. Tilt. Reportedly, the company name was created when Tilt’s shoe-making father fashioned a logo featuring a big “T” (for Tilt, of course) framed by a diamond, which signified high quality. From its beginnings manufacturing touring cars, the company later became known for its trucks. By 1967, as a subsidiary of White Motor Company, it was merged with Reo Motor Company to become Diamond Reo Trucks, Inc.

During World War II, Diamond T produced a classic heavy truck in the 980/981, a prime mover which was quickly acquired by the British Purchasing Commission for duty as a tank transporter tractor. Coupled with a Rogers trailer, the truck gave sterling service with the British Army in North Africa Campaign, where its power and rugged construction allowed the rescue of damaged tanks in the most demanding of conditions. In addition Diamond T built the entire range of the G509 series 4 ton 6X6s, including cargo, dump, semi tractor, and wrecker trucks, as well as some lighter trucks, and even G7102 half tracks. Diamond T ranked 47th among United States corporations in the value of World War II military production contracts.Diamond T manufactured two pickup trucks: the Model 80 and the Model 201. Both pickups were powered by the Hercules QX-series 6-cylinder engines. The Model 201 was produced from 1938 to 1949.

Cars

Diamond T produced automobiles in Chicago from 1905 to 1911. The models produced were powerful touring cars of up to 70 hp.

| Model and Year | Engine | HP | Wheelbase |

|---|---|---|---|

| Diamond T(1907) | Four-cylinder | 40 | 114" |

| Diamond T(1908) | Four-cylinder | 50 | 114" |

| Diamond T(1909) | Four-cylinder | 50 | 114" |

| Model D(1910) | Four-cylinder | 35 | 108" |

| Model E(1910) | Four-cylinder | 45 | 124" |

| Diamond T(1911) | Four-cylinder | 45 | 124" |

Trucks

Military Trucks

The Diamond T 980 and 981 was a 12-ton hard-cab 6x4 truck. Powered by a Hercules DFXE diesel engine developing 201 hp (150 kW) and geared very low, it could pull a trailer of up to 115,000 lb (52,000 kg) and proved capable of the task of moving the heaviest tanks then in service. Early trucks used a standard Diamond T commercial cab, also used by the 4-ton G509 trucks. In August 1943 it was replaced with an open military cab. A long butterfly hood had vertical louvers along both sides.

A short ballast body was mounted behind the winch. There were closed tool compartments along both sides, two open containers in the front, and a bottom-hinged tailgate. The spare tire was mounted in the front. The box could hold 18,000 lb (8,200 kg) of ballast to increase traction on the rear tandem axles.

When paired with the M9 rogers trailer, the unit was designated the M19 tank transporter

The Diamond T Model 968 Truck, Cargo, 4 ton, 6x6 (G509) was produced during World War II, beginning in 1941. Early production used civilian instruments and other parts. The designation was changed to Model 968A when military standard instruments and components were substituted. It was produced with both the closed metal cab and, by 1943, open soft-top military cab. The final version was 968B. Its military role was as an artillery prime mover and for general cargo transport.

The Diamond-T 968 Truck, Cargo, 4 ton, 6x6 was powered by the 6 cyl., 529 cu. in. Hercules RXC engine that developed 106 hp. mated to a five speed manual transmission and two speed transfer case. The truck weighed 18,450 pounds and could tow 25,000 pounds.

The Diamond-T Model 969 Wrecker was built on the same G-509 chassis. Diamond-T began building the 969 series in 1941. After less than two dozen were built using civilian components, the instruments and other parts were changed to military standard and the designation became 969A. Both closed metal cabs and open, soft-top cabs were built for the 969A. The soft-top cabs could be fitted with a machine gun ring mount. There was a 969B model for export, but these were not used by U.S. forces.

The Diamond-T 969A 4-ton, 6x6 Wrecker was powered by the 6 cylinder, 529 cu. in. Hercules RXC engine that developed 106 hp. mated to a five-speed manual transmission and two-speed transfer case. It was equipped with the Holmes W-45 heavy-duty military wrecker bed with its twin boom and two 5-ton winches at the front of the bed as well as a front-mounted winch. A variety of other recovery equipment was carried, along with its own air compressor.

The vehicle weighed 21,350 lbs. and could tow 25,000 pounds. It was 292 in. long, 100 in. wide, and 116 in. high.

The 970 dump truck was built on the standard G509 chassis. The spare tires were mounted between the cab and bed. The tailgate could be opened at the top or bottom. Originally the dump trucks were not fitted with front winches in order to reduce front axle loading. After a Corps of Engineers request, winches were fitted from June 1944 onwards. The trucks had air brakes and trailer brake controls.